On July 22, 2023 — a Tesla (TSLA) employee, Peter Hinterdobler, was injured by a FANUC robot while working at the company’s Fremont car factory.

According to Peter, he was assisting a Tesla engineer in disassembling a robot when the arm of the robot released without any warning. Along with the arm, an 8,000-lb counterbalance also fell and injured the Tesla employee.

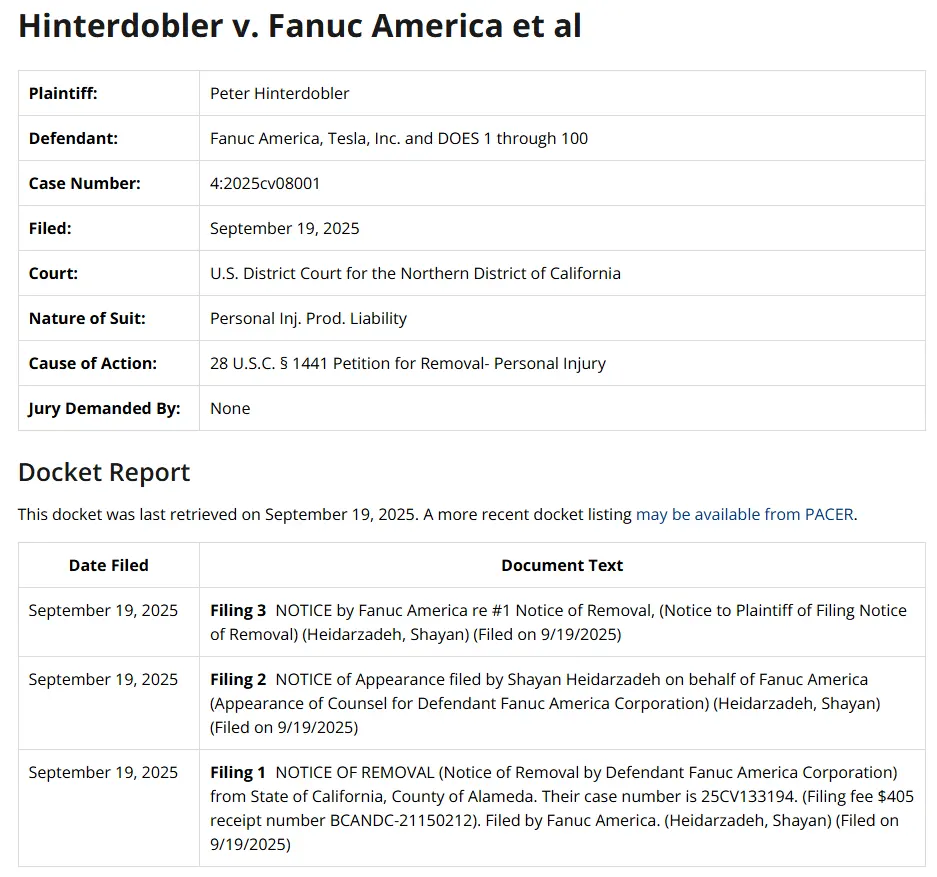

Because of the injuries, Peter sued Japanese robot manufacturer FANUC and Tesla, Inc., claiming damages of 51 million dollars. Mainstream media (MSM) picked-up the story. A rare chance to point out safety-related working conditions at Tesla factories.

Peter has sued Tesla, Inc., and FANUC America Corp. in the Superior Court of California. According to the plaintiff, $1 million has already been spent on his medical bills due to the incident. He’s asking for $51 million in lifetime damages because of injuries, decreased work ability, and lost wages.

According to the legal document seen by the PEOPLE magazine, Peter claims that he was struck by the robot’s arm with “substantial force”. This hit caused him “to be thrown to the floor and to lose consciousness, among other injuries”.

Tesla and FANUC haven’t released an official statement on this incident and the lawsuit. However, in a personal capacity, a Tesla engineer commented on it on LinkedIn.

LinkedIn page Six Degrees of Robotics posted the story on the platform, to which Lead PCB Design Engineer at Tesla Motors, Carl Schattke, responded.

“Wonder how many rules he broke getting that to happen. Everyone is trained on lockout tag out,” Carl commented on the lawsuit.

Carl Schattke is working at Tesla for more than 15 years, and he knows how seriously safety measures are taken at Tesla factories. In the image above, we can see that a large FANUC robot is working on a Tesla car’s body-in-white (BIW), and a security fence separating human workers is clearly visible in the background.

Other industry veterans also commented on this post, saying the plaintiff should’ve followed the safety instructions strictly to avoid this sort of incident. FANUC has strict SOPs defined to operate and handle its industrial robots.

He may make some money from Tesla but I would be reaaaaal surprised if he gets anything from fanuc. Safety is at the forefront of all robotics companies and it’s documented everywhere. Fanuc has DCS for this very reason.

Lucas Richardson on LinkedIn

Reading the court filings, it appears this occurred during maintenance/repairs. If you remove a motor without placing in neutral position and supporting, gravity will do what gravity does. Taking all the bolts out of a structural beam and it falls on you is in the same category. This appears to just be a workers comp incident. Nothing specific to the controls and safety interlocks.

D.L. Lewis on LinkedIn

Stay tuned for constant Tesla updates, follow us on:

Google News | Flipboard | X (Twitter) | WhatsApp Channel | RSS (Feedly).

Related Tesla and Elon Musk News

- Outright purchase of Tesla FSD is still available for the Model S and X (Luxe Package), and the Cyberbeast

- Tesla adds 60 planned locations to the Semi’s US Mecharger map, get the complete list

- Tesla update 2026.2.3: hidden features, Service Mode FSD updates, battery recalibration, more

- Tesla update 2026.2.3 goes wide release, explore new features and release notes

- Lemonade offers 50% insurance discount for Tesla owners using the safer Full Self-Driving (FSD)

- Starship Booster 19 survives the cryo test, Flight 12 updates from Starbase

I work on these robots, and what it sounds like happened was the machine brakes got energized for some reason while the motors weren’t. I regularly do this, but never with an arm. The brakes being energized means they turn off, and if the motors can’t catch the arm (not energized), the arm falls.

He can get somewhere with Tesla I think because they should have trained him on this. The Tesla guy’s stupid comment I think shows he thinks this some generic lock out tag out issue which it isn’t. There should have been a fixture to put to arm into, and that would have met lock out tag out. If that wasn’t present, normal lock out tag out doesn’t do anything.

This is really specific. He shouldn’t have pulled FANUC in because they warn you about this specific thing but it’s buried deep in the manual the customer (Tesla) has tossed into a filing cabinet somewhere. Tesla is for sure at fault, likely for not providing adequate training and/or the right fixture. This is not someone thing you can do on accident, and it’s not something anyone should teach you to do without first training you on the risks.

Thanks for your technical input on this.

But it is something you could do if you do not follow safety protocols.

Maybe he should pay Tesla for violation of work rules.

Lock out tag out doesn’t prevent these robots from moving when disassembling them. If a servo motor is removed from an unsupported axis….they will move or fall. Anytime that we worked on them we, they were supported with a gantry crane or a chain hoist attached to an ibeam. Tesla is serious with Lock out tag out. It’s always easy to assume. On another note, there’s many situations where you are in the cell jogging the robot where you could injure yourself or another coworker.

Step one: remove servo motor and servo motor brake assembly without taking any necessary precautions

Step two: unsupported arm falls on you because you’re working in an unsafe fashion

Step three: ????

Step four: PROFIT!

When it comes to Tesla, everyone’s trying to cash in on the “evil” Elon Musk image created by legacy media. This same robot is used in every auto plant. This is just like the black cleaning guy who sued Tesla for a discriminatory environment because somebody (I suspect it was he himself) wrote the n word in the bath room and so Elon Musk has to pay millions. The guy was so “traumatized” that a court awarded him $150 mil to remove his trauma by spending the rest of his life on booze and strippers.