2020 was the best year for Tesla despite the challenges the world and the automaker faced due to the unprecedented COVID-19 situation. Tesla scored record straight 4 profitable quarters in a single year for the first time in its history.

I thought it would be great to assemble the Tesla Q4 2020 Earnings Call, the company’s 2020 financial report PDF (below), and add a summary of answers that Elon Musk gave during the call.

The biggest surprise of this earnings call was Elon Musk’s announcement of the launch of the design refreshed 2021 Tesla Model S and Tri-Motor Plaid performance variants.

The ones who like to listen can play the following audio of the Tesla Q4 Earnings Call, the readers can skip down for the highlights of the call.

Special thanks to my friends over at CleanTechnica for posting the improved and trimmed-down audio version to YouTube with clear markers on who’s talking as the timeline passes.

TSLA Q4 2020 Earnings Call (audio)

Tesla Q4 2020 Earnings Call assorted highlights

Record production & deliveries

With the Tesla Gigafactory Shanghai and the US Fremont factory in full throttle, Tesla was able to achieve 500k+ units production and almost the same amount of deliveries in Q4 2020. This is more vehicles produced compared to Tesla’s entire history (talk about a growth story). The S curve has just started to take off.

Tesla Fremont car factory has a total annual production capacity of 600k cars (Model S/X 100k & Model 3/Y 500k). With Giga Shanghai’s ability to produce 450k Model 3 and Model Y cars, Tesla is now able to produce more than 1 million cars a year (source: see 2020 Tesla report PDF below).

According to Tesla estimates, limited production of Tesla Model Y at the Gigafactory Berlin will start later this year, and if Giga Texas starts Cybertruck production this year, Tesla might just be able to pull the 1 million car deliveries mark this year.

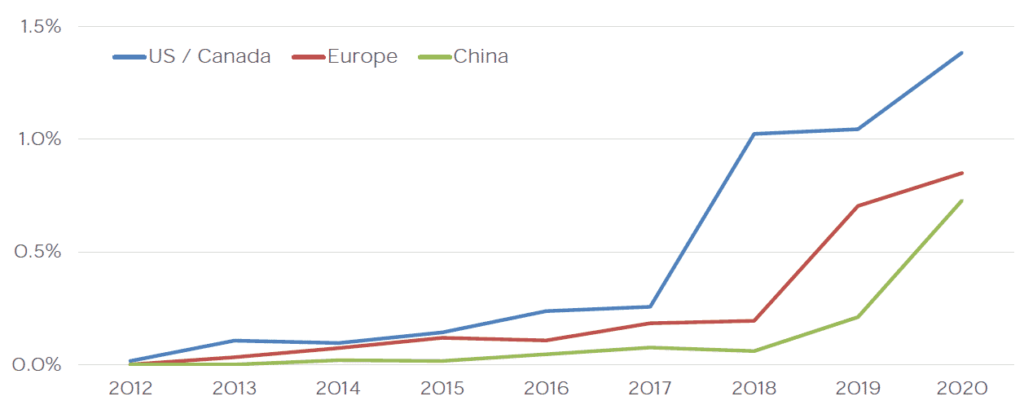

According to Tesla’s fiscal year 2020 update report, the automaker now holds around 1.4% of the total US automotive market share. For Europe and China, the share is just climbing towards 1% (graph and report below).

2020 was a turning point for Tesla in terms of profitability. I would believe this is just the beginning. We think 2021 is going to be even more exciting.

Elon Musk

FSD, Robotaxis, and 2X+ revenue

According to Elon Musk, there are almost 1,000 beta testers for the Tesla Full Self-Driving Beta including him at the moment. He recommends watching FSD Beta videos that some users continuously post online, these videos show a good amount of progress in the right direction.

With the success of Tesla FSD, a Robotaxi fleet would bring a 60 hours per car per week utility, and for Tesla, it will be pure profit as the software would be already in place. 60 hours a week is 5X of the 12 hours a week average utility of a vehicle. Even if the car becomes twice as useful, that would mean doubling the revenue of the company. If you make $50B worth of cars, it would be $50B incremental profit, says Elon Musk.

Other FSD, HW4 points:

- We need to make FSD 100 – 200% better than an average human driver. This is happening rapidly as Tesla is gathering a lot of Neural Net training data.

- Dojo will be the best neural net training supercomputer in the world by possibly an order of magnitude.

- Tesla is open to offering its neural net training and FSD software licenses to other automotive companies.

- The next-gen Tesla FSD supercomputer chip (Hardware 4.0/HW4) is expected to be at least 3 times more powerful than the current HW3 chip but FSD is completely achievable on HW3.

- HW4 will need to be paired with high-resolution cameras and some other equipment in Tesla cars will need to be changed (in newer production, of course. I think this is substantially far in the future).

- The game-changer in full self-driving will not be HW4 but getting the software to work and getting all the Tesla neural nets to use video labeling is going to be the real game-changer, says Musk.

Tesla 4680 cells and battery production capacity

- Telsa’s 4680 cell pilot production plant in Bay Area, California is possibly in the world’s Top 10 battery production plants.

- Tesla battery production is estimated to reach 100 GWh per year by 2022 which will be 50% functional of the 200 GWh installed capacity. Gigafactory Berlin might be an additional cell production facility in addition to Fremont and Giga Nevada next year.

- Tesla’s own cell production is only going to supplement the company’s cell suppliers’ production and deliveries. Currently, CATL, Panasonic, and LG Chem provide batteries for Tesla cars and power products.

- The battery cost, efficiency, and production capacity goals set at the Battery Day last year will be realized in the next 3-4 years.

Customer Service Improvements

Tesla Director of Automotive Jerome Guillen said that within the last two years the frequency of service visits by customers is reduced by one-third. Tesla has taken two steps to improve the after-sales customer service experience; #1 by improving the quality of the products and #2 by offering Tesla Mobile Service.

Tesla Mobile Service takes care of about 40% of customer service requests in North America which the automaker is trying to bring 50% this year. Tesla has 140 service centers in North America and 100 out of those 140 give appointments to customers in less than 10 days, Jerome Guillen said.

By developing strategies and processes, the company is trying to lessen the service time to fewer and fewer hours needed per car. In the near future, most of the Telsa service appointments will be moved to the Tesla Mobile App and phone appointments will vanish with time.

Cybertruck Giga Casting

According to Elon Musk, Tesla will soon be ordering the equipment necessary for Cybertruck production. Gigafactory Austin will be the first Tesla manufacturing facility to start the Cybertruck production.

Tesla will use even bigger casting machines than the ones currently being used for the Model Y. Cybertruck casting will be done using an 8,000-ton casting press vs. the 6,000 ton used for the Tesla Model Y.

Elon Musk thinks Tesla will be lucky if it’s able to start deliveries towards the end of this year, he expects volume production to start in 2022.

Related: Tesla has ordered its first 8,000-ton Giga Casting machine

Tesla Van, Semi Truck, more

- A Tesla Semi requires 5 times more battery cells than a Tesla car (probably compared to a Model 3/Y).

- Tesla Van (Model V) will be made at some point in the future but only when the cell supply constraint is resolved.

- All newly produced vehicles i.e. Model S, 3, X, and Y are now equipped with the heat pump system.

Stay tuned for constant Tesla updates, follow us on:

Google News | Flipboard | RSS (Feedly).